Lithium

The Lithium Market

Supply & Demand

Lithium Products

Global Lithium Reserves

Lithium Articles

Video Gallery

Lithium: Technology

Lithium Revolution

The Lithium Market

GLOBAL LITHIUM RESERVES

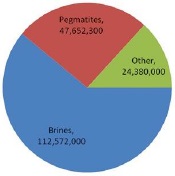

Global estimates suggest there are more than 30 million lithium resources, however, it is important to know that most deposits are not economically viable. For instance, some of the deposits, both brines and hard rock, may have high levels of impurities that make processing very costly, while others are in isolated parts of the world and would require high infrastructure expenditures, deeming them uneconomical. In the case of brines, the weather in some regions is not appropriate for the solar evaporation process. There are also many other factors, thus it is necessary to spend a significant amount of time and resources to determine the feasibility of these projects before considering them as viable resources (Euro Pacific- Canada, August 2013)

Source USGS

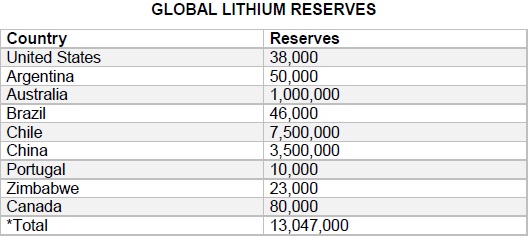

According to the United States Geological Survey (USGS) it is estimated that the global lithium reserves are in the 13 million tons. These estimates exclude lithium occurrences and resources that have not proven economic.

*Global Lithium Reserves from USGS (2011)

BRINE DEPOSITS ARE NOT ALL THE SAME

Brine based deposits are located all over the world but only a small number of them are considered to be economical for the recovery of lithium, potash, boron and potassium. We hear the term "playa" and "salar" which primarily means the same thing, a salt encrusted depression that may or may not be the basin of an evaporated lake.

The best explanation of lithium brine based deposit can be found the USGS (United Stated Geological Survey): Read More

Some of the more relevant determining factors for an economical brine based Lithium deposit are as follows:

For the sake of this narrative we are excluding the evaporation and development of hard rock lithium mining, as it is a historical fact that hard rock lithium mining is at least double the cost of brine based operations.